Feature

- Compact, lightweight, desktop design

- Integrated weighing, temperature, pH/conductivity

- Magnetic drive, seal-free mixing paddle

- Touchscreen control, easy to operate

- Compatible with LeKrius® mixing bags

- GMP-grade compatible

Application

The Minwind Tabletop Mixing System is applicable to biopharmaceutical R&D and production:

- Intermediate homogenization

- Lab-scale mixing

- Adjuvant processing

- Semi-finished prep

- Viral inactivation

- Pre-filling homogenization

Design Feature

The Minwind Tabletop Mixing System is designed for sterile liquid mixing, supporting homogenization from 500 mL to 30 L and bridging volume gaps in traditional systems. It uses magnetic coupling for contactless power transfer, eliminating shaft seal contamination. Pre-sterilized bags require no cleaning, and the transparent design allows real-time monitoring,ensuring efficient, safe, and sterile mixing for small-volume applications.

Software Control and Functions

- Compact design with small footprint

- Lightweight design enables easy benchtop deployment in lab-scale or controlled environments.

- Magnetic drive, seal-free, contamination-free

- Modular sensor ports pre-configured

- Compatible with 75% ethanol, isopropanol wiping

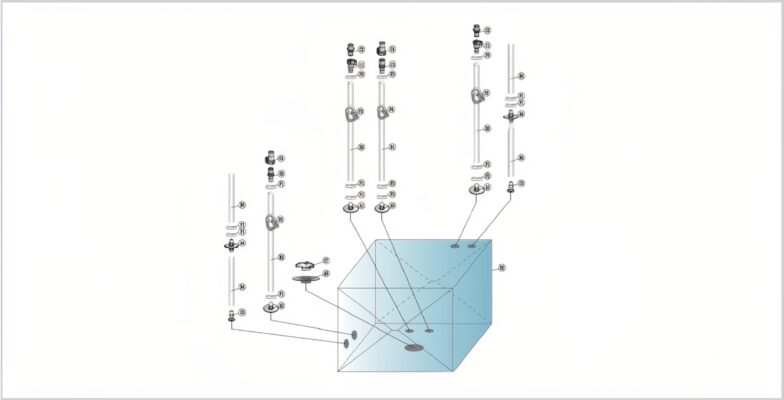

Functional Modules

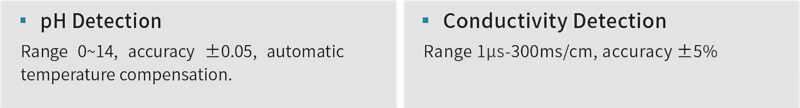

Process Detection Module

Software & Human‒Machine Interface (HMI)

- Proprietary software with fast response

- Bilingual (Chinese-English) support

- Easy type: 7″ display; Power type: 15.6″ HD touchscreen with clear UI

- Layered menus showing mixing speed, temp, pH/conductivity, and weight in real time

- Supports user permissions, audit trail, data logging, and batch reporting

- Ethernet port for SCADA, MES, and centralized system integration

Compliance

- Four-level permission control with 7 automatic logs (audit trail, operation, etc.) and PDF report export

- fully GMP compliant

- Level 2 electronic signature meeting 21 CFR Part 11 data integrity standards

- CE certified, compliant with EU regulations

Compatible Consumables

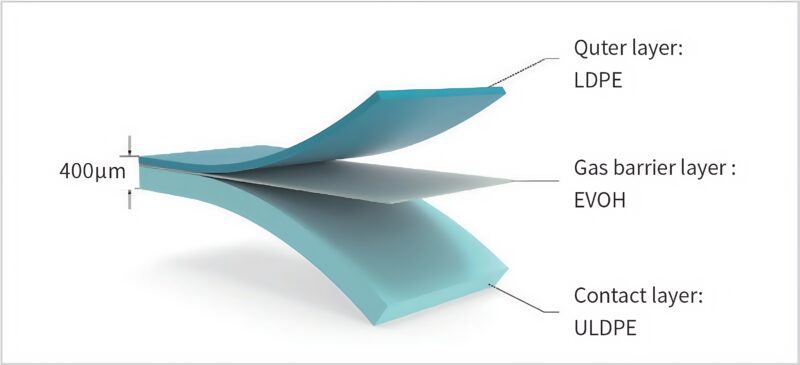

Independently developed:LeKrius® Film

- Safety

- Robustness

- Sustainability

LeKrius®Film is a co-extruded multi-layer film meticulously made of LDPE-EVOH-ULDPE materials.

These materials undergo stringent biocompatibility testing, guaranteeing an exceptionally low level of extractables.

The film has a thickness of 0.4 mm and is sterilized using gamma irradiation at a dose exceeding 25 kGy.

The maximum radiation tolerance is 50 kGy.

Both the raw materials and the manufacturing process of the LeKrius® film are free from TSE/BSE risk.

Advantages

- Comprehensive qualification with rigorous biocompatibility tests

- Great performance of cell cultivation, extremely low level of extractables and leachabels

- Assurance of supply and batch-to-batch consistency

- Low gas transmission, high sealing strength and high resistance to blending and rubbing